The M!OS-based garden pump control system enables intelligent automation of your irrigation system, including frost protection at temperatures below 5 °C, automatic pre-delivery pressure optimisation, and power-controlled (PWM) operation. And you don’t need any programming knowledge!

The challenges of automation

The following problems often arise with conventional garden pump control:

- Activation faults occur when the main switch is turned off (e.g. during maintenance or holidays).

- Frost damage at low temperatures.

- Insufficient pre-feed pressure impairs the pump’s performance and service life.

- Processes that are not time-controlled (e.g. in the evening at >20 °C).

- Lack of a user-friendly control system offering access to non-technicians.

System components at a glance

Temperature sensor

For monitoring (< 5 °C = no start)

Digital main switch

Safety shutdown e.g. maintenance/holiday

Pressure switch

For pre-feed pressure measurement (approx. 25 %)

Manual push-button

For an optional two-hour run

Indication light

As visual feedback in automatic mode

Pump

Efficient, frost-protected garden irrigation

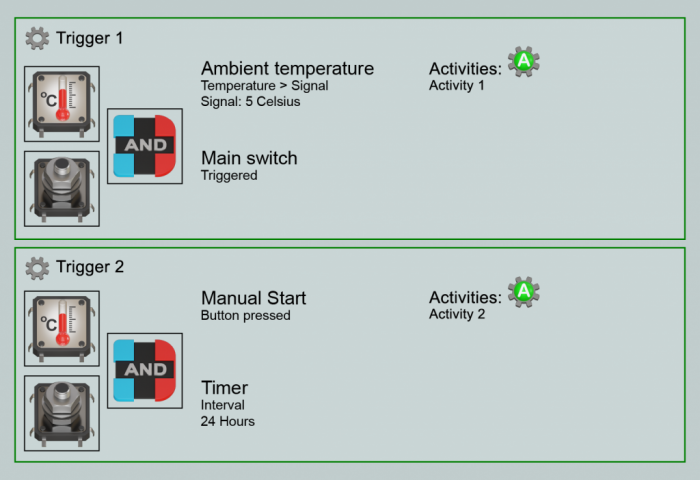

How automation works with M!OS & M!OS-CT

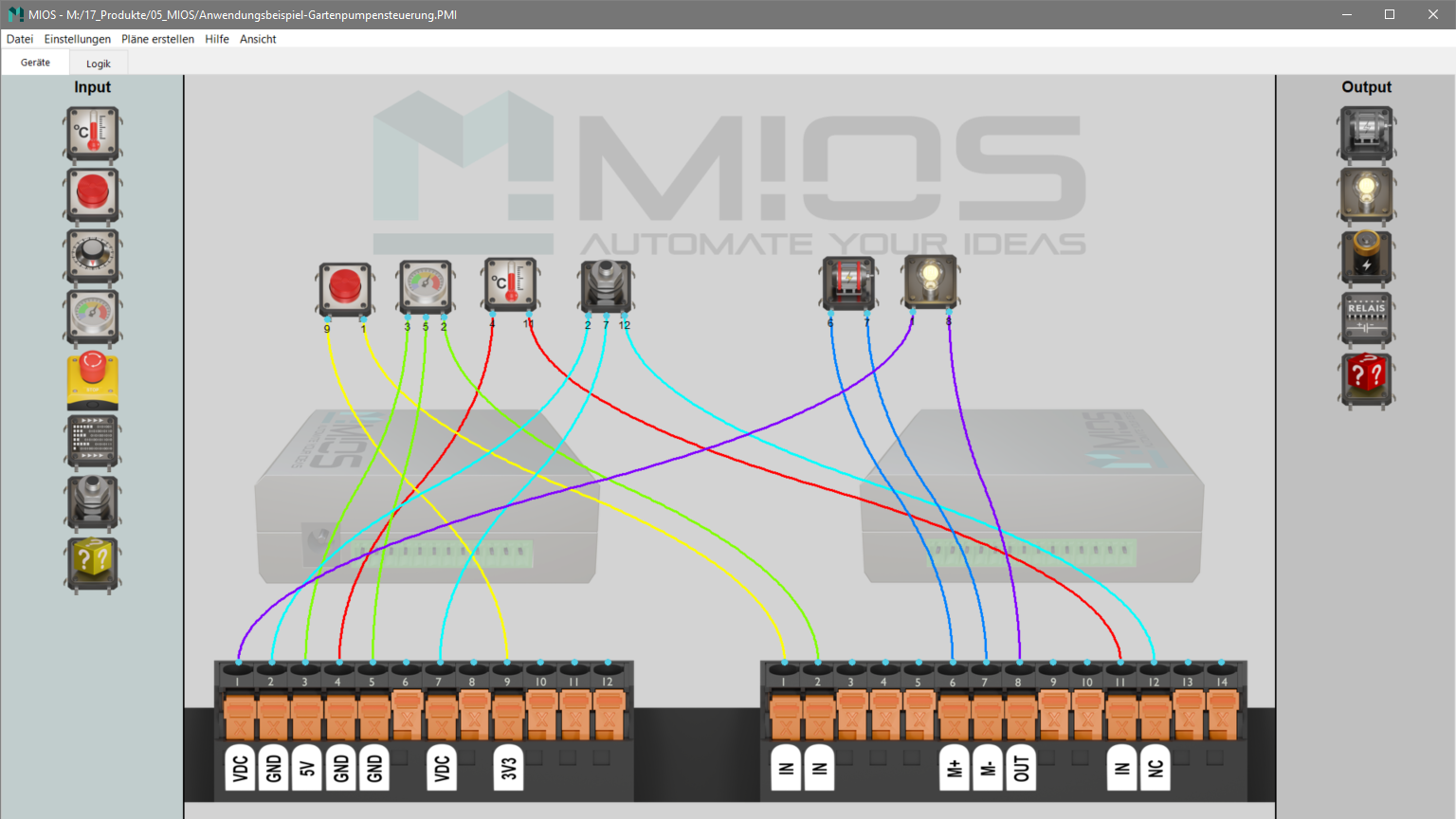

With M!OS-CT Configuration without programming with graphical user interface

The M!OS-CT software offers an intuitive graphical user interface. Devices are automatically detected and preconfigured pin assignments are suggested. Processes can be created using drag-and-drop, eliminating the need for any code. This makes setup efficient and minimises the risk of errors.

Sensor, push-button, light and pump as active or PWM output Set up smart components

Thanks to extensive preconfigured device profiles, temperature sensors, buttons, indicator lights and pump actuators can easily be set up via M!OS-CT, with automatic connection assignments. Precise power control is also possible with PWM outputs.

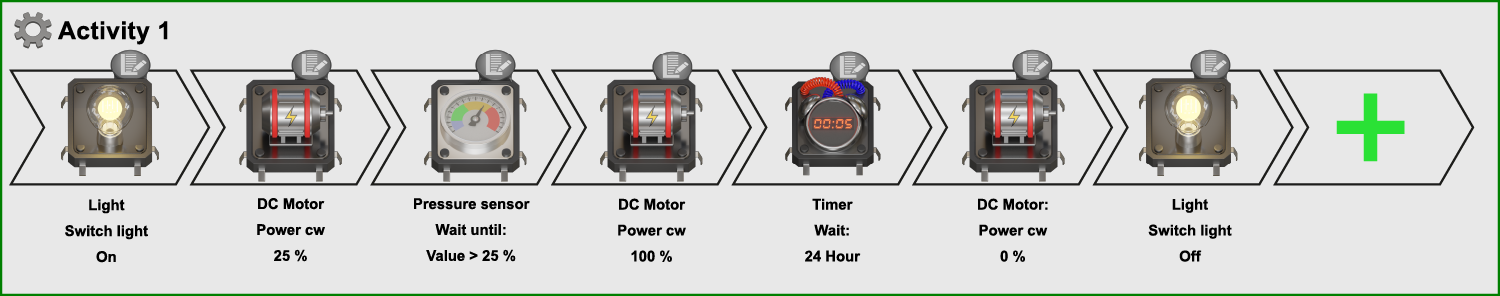

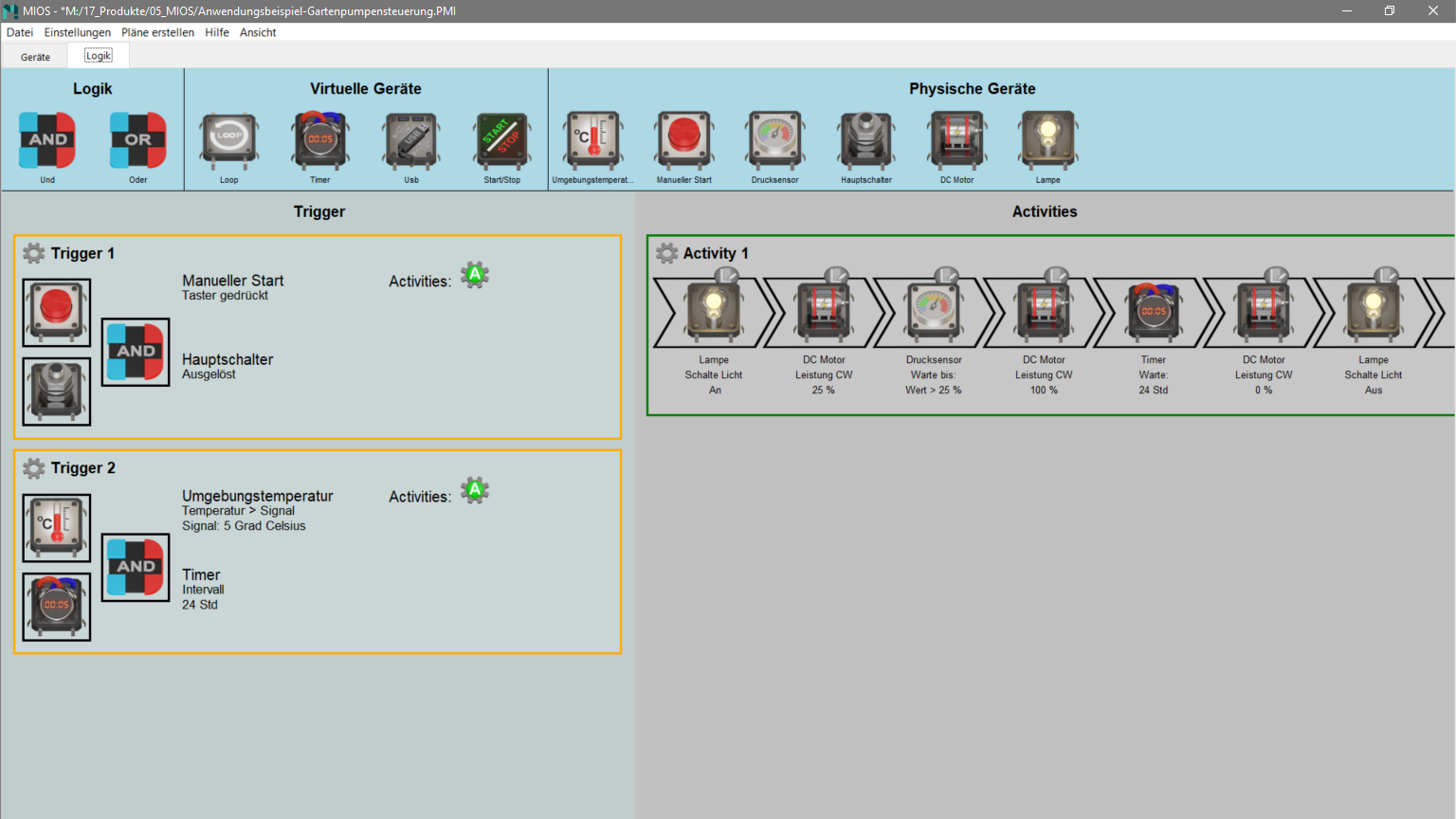

Intelligent control logic to automate your garden pump

Main switch activates the entire control system

The main switch serves as a central safety shut-off. It can be used during maintenance or holidays. It checks whether the automation concept remains active.

Temperature condition: No operation below 5 °C

This is where frost protection comes in, as if temperatures are too low, the pump remains deactivated to prevent damage.

Pressure control: Full load with sufficient pre-feed pressure

The pump output automatically adjusts to the existing pre-delivery pressure and, when the pressure is stable, the pump operates at full power.

Daytime logic: Activate automatically in the evening from 5 p.m. at > 20 °C

Thanks to time-sensitive logic, the system can be configured to automatically water in the evening from 5 p.m. onwards when it is warm outside – a smart combination of temperature and time control.

Time limit: It switches off automatically after two hours.

The pump is designed to switch off automatically after a maximum of two hours, which is ideal for preventing overflow or overload.

Manual button also triggers a 2-hour run

If required, a button can be used to manually start a two-hour watering cycle, which is useful for short-term use, such as when watering new arrivals.

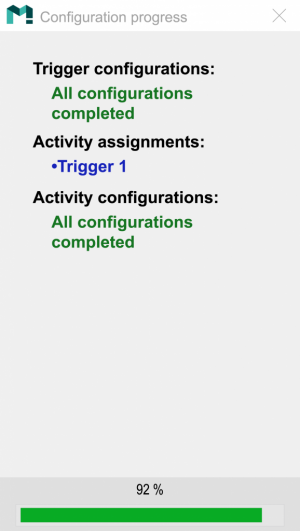

Validation by means of a plausibility check

Before commissioning, M!OS carries out a plausibility check to ensure that the configuration and cabling are logically compatible. This detects incorrect connection assignments or configuration errors, thereby minimising malfunctions in the field.

Real-time mode (live mode) or independence via headless mode

M!OS offers two operating modes:

- Live mode: M!OS delivers control and measurement data in real time directly to a host via an active connection.

- Headless mode: Once uploaded, the system runs completely independently, which is ideal if a permanent connection is unavailable or independence is required.

A look at the software

More information about the product

Automate your garden now!

Are you interested?

Our project manager Andreas Hofmann will be happy to answer your questions and assist you with the implementation.